Duct Manufacturing

SSV Insulation specializes in providing comprehensive solutions for duct manufacturing, catering to various industries and applications. Here’s a detailed description of SSV Insulation’s “duct manufacturing” services, including key features and application industries

Key Features

SSV Insulation’s duct manufacturing services include customized design capabilities to create ductwork solutions that meet the exact specifications and performance requirements of each project. This ensures optimal functionality and efficiency.

The ductwork components are fabricated using high-quality materials such as galvanized steel, stainless steel, aluminum, or specialized alloys, depending on the application, environmental conditions, and industry standards.

SSV Insulation employs advanced manufacturing techniques and equipment to ensure precise fabrication of ductwork components, including straight ducts, elbows, transitions, dampers, and fittings. This precision enhances system performance and minimizes air leakage.

Duct manufacturing includes sealing joints and seams to prevent air leaks and improve energy efficiency. Additionally, insulation options are available to enhance thermal performance, reduce condensation, and meet insulation standards.

The ductwork components are designed and fabricated for durability, corrosion resistance, and long-term reliability, ensuring a robust HVAC system with minimal maintenance requirements.

SSV Insulation ensures that all duct manufacturing processes adhere to industry standards, codes, and regulations, including duct construction standards, fire safety requirements, and environmental guidelines.

Fabricated ductwork components are designed for easy and efficient installation, saving time and labor costs during HVAC system assembly and installation.

SSV Insulation’s duct manufacturing services offer cost-effective solutions tailored to meet project budgets without compromising on quality, performance, or safety.

Applications

Residential

Buildings

Commercial

Structures

Industrial

Facilities

Educational

Institutions

Healthcare

Facilities

Flexible Duct Insulation

SSV Insulation introduces our Flexible Duct Insulation, a cutting-edge product designed to provide effective thermal insulation and versatility for a variety of HVAC (Heating, Ventilation, and Air Conditioning) applications. Crafted with precision from high-quality materials, this insulation solution is engineered to enhance energy efficiency, ensure optimal temperature control, and contribute to the overall performance of residential, commercial, and industrial HVAC systems.

Key Features

Our Flexible Duct Insulation excels in thermal performance, effectively minimizing heat transfer within HVAC ducts. This contributes to energy conservation, reduced operational costs, and improved overall system efficiency, ensuring that conditioned air reaches its destination without unnecessary heat loss or gain.

The flexibility of our insulation allows for easy installation around bends, curves, and irregular shapes within ductwork. This flexibility ensures a seamless and efficient application, making it suitable for a wide range of HVAC systems and configurations.

SSV Insulation offers Flexible Duct Insulation in various thickness options, providing flexibility for customized solutions based on specific insulation requirements. This allows for tailoring the insulation to achieve optimal thermal performance for different HVAC applications.

Crafted from durable and resilient materials, our flexible duct insulation is designed to withstand the rigors of HVAC operation. It maintains its integrity over time, providing consistent thermal performance and contributing to the longevity of the entire HVAC system.

The insulation is engineered to control condensation within the ductwork. By preventing moisture buildup, it helps maintain the integrity of the HVAC system, mitigating the risk of corrosion and mold growth. This feature is crucial for ensuring a healthy indoor environment.

In addition to its thermal properties, Flexible Duct Insulation offers effective sound absorption within duct systems. This feature helps minimize the transmission of noise, enhancing the acoustic comfort of indoor spaces.

Applications

Residential HVAC Systems

Commercial Building Ventilation

Industrial Air Handling Units

HVAC Retrofitting Projects

Aluminium Plain Sheet

Aluminium GI Sheet

SSV Insulation proudly presents our Aluminium Plain Sheet Insulation—a versatile and high-performance insulation solution designed to provide effective thermal protection, durability, and adaptability for a variety of industrial, commercial, and residential applications. Crafted from high-quality aluminum, this insulation product is engineered to enhance energy conservation, ensure longevity, and meet diverse insulation needs.

Key Features

The aluminium plain sheet serves as an excellent thermal reflector, minimizing heat absorption and transfer. This feature contributes to superior insulation performance, maintaining desired temperatures in various environments.

Aluminium is inherently resistant to corrosion, rust, and degradation, ensuring the longevity and structural integrity of the insulation material. This durability makes it suitable for applications in diverse and challenging environments.

Aluminium Plain Sheet Insulation is highly versatile and adaptable to various applications. It can be utilized for roofing, wall cladding, and other insulation needs in both residential and commercial construction projects.

Aluminium is known for its lightweight properties, facilitating easy handling and installation. This characteristic simplifies construction processes, reduces labor costs, and allows for efficient application in various scenarios.

The reflective surface of the aluminium sheet enhances energy efficiency by reducing the absorption of solar radiation. This makes it suitable for applications where heat gain from sunlight is a consideration.

Aluminium exhibits excellent resistance to weather elements, making it suitable for outdoor applications. It withstands exposure to sunlight, rain, and varying temperatures, ensuring consistent insulation performance over time.

Applications

Roof Insulation in Residential and Commercial Buildings

Wall Cladding for Enhanced Thermal Efficiency

Insulation for Industrial Facilities

HVAC (Heating, Ventilation, and Air Conditioning) Duct Insulation

Energy-Efficient Construction Projects

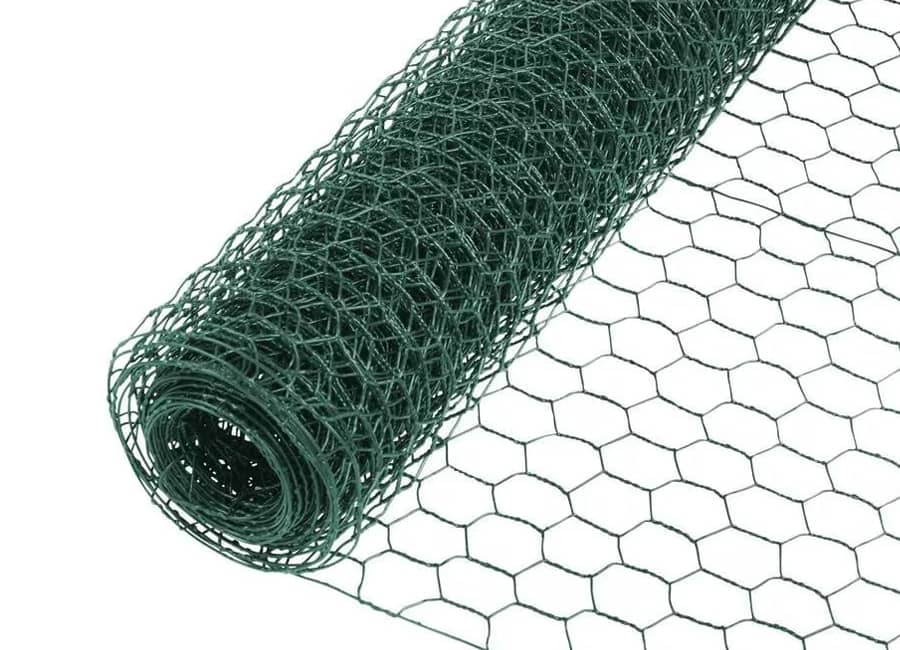

GI Wire Netting

Galvanized iron (GI) wire netting is a versatile and widely used material in construction, agriculture, fencing, and other applications where a durable and corrosion-resistant mesh is required.

Key Features

GI wire netting is typically made from high-quality steel wire that has been coated with a layer of zinc through a process called galvanization. This zinc coating provides excellent corrosion resistance, making the wire netting suitable for outdoor use and exposure to moisture and harsh weather conditions.

GI wire netting is available in various mesh sizes and wire gauges to suit different applications. The mesh size refers to the spacing between adjacent wires in the netting, while the wire gauge indicates the thickness or diameter of the wire. Common mesh sizes range from small, fine meshes used for insect screening to larger meshes used for fencing and construction reinforcement.

Galvanized iron wire netting is known for its strength and durability. The galvanization process enhances the wire’s resistance to corrosion, rust, and mechanical damage, ensuring a long service life even in harsh environments. This makes it ideal for applications requiring sturdy and reliable mesh, such as fencing, animal enclosures, and construction reinforcement.

GI wire netting is a versatile material with a wide range of applications. It can be used for fencing to enclose gardens, agricultural fields, livestock, and poultry farms. It is also used for screening windows and doors to keep out insects while allowing airflow. Additionally, GI wire netting is employed in construction as reinforcement for plastering, concrete, and masonry work to improve structural strength and prevent cracking.

GI wire netting is easy to install and can be cut to size using simple tools like wire cutters or shears. It can be attached to existing structures or supports using nails, staples, or wire ties. For fencing applications, it can be stretched between posts or attached to wooden or metal frames to create a secure enclosure.

Compared to other materials like stainless steel or aluminum, galvanized iron wire netting is often more cost-effective while still providing excellent corrosion resistance and durability. This makes it a popular choice for budget-conscious projects without compromising on quality or performance.

While GI wire netting is highly resistant to corrosion, periodic maintenance may be required to remove dirt, debris, or vegetation that can accumulate on the surface over time. Regular inspections and cleaning can help prolong the lifespan of the netting and ensure optimal performance.

Applications

Industrial

Processes

HVAC (Heating, Ventilation, and Air Conditioning) Systems

Commercial

Building Insulation

Residential

Construction

Equipment

Insulation

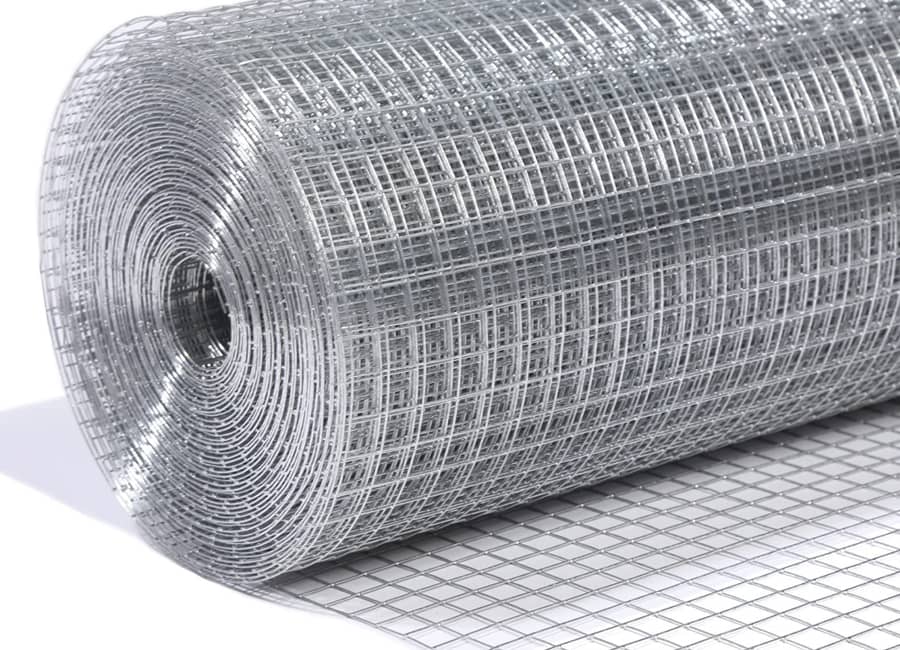

GI Wild Mesh

GI wild mesh, also known as galvanized iron wild mesh, is a type of wire mesh commonly used in agricultural and horticultural applications to protect crops and plants from wild animals and pests.

Key Features

GI wild mesh is typically made from galvanized iron wire, which is steel wire coated with a layer of zinc through the process of galvanization. This zinc coating provides excellent corrosion resistance, making the mesh suitable for outdoor use and exposure to harsh weather conditions.

GI wild mesh comes in various mesh sizes and wire gauges to suit different applications and levels of protection. The mesh size refers to the spacing between adjacent wires in the mesh, while the wire gauge indicates the thickness or diameter of the wire. Common mesh sizes range from small, fine meshes to larger meshes, depending on the type of crops and the size of the pests being targeted.

GI wild mesh serves as a physical barrier to prevent wild animals, birds, and pests from accessing crops and plants. It can be installed as fencing around agricultural fields, orchards, vineyards, and garden plots to deter animals from damaging or eating the produce. The sturdy construction of the mesh provides reliable protection against larger animals such as deer, rabbits, and birds.

In addition to protecting crops from wildlife, GI wild mesh has other uses in agriculture and horticulture. It can be used to create trellises for supporting climbing plants such as tomatoes, beans, and cucumbers. The mesh can also be employed as a barrier to prevent soil erosion or to support netting for shade or frost protection.

GI wild mesh is relatively easy to install and can be cut to size using simple tools such as wire cutters or shears. It can be attached to existing structures or posts using nails, staples, or wire ties. For larger installations, it can be stretched between posts or attached to wooden or metal frames to create a secure perimeter.

The galvanized iron construction of the mesh provides excellent durability and resistance to rust and corrosion, ensuring a long service life even in harsh outdoor environments. This makes GI wild mesh a cost-effective solution for long-term crop protection.

While GI wild mesh requires minimal maintenance, periodic inspections may be necessary to ensure that the mesh remains intact and properly secured. Any damage or areas of weakness should be repaired promptly to maintain the effectiveness of the mesh as a barrier against wildlife.

Applications

Industrial Piping Systems

HVAC (Heating, Ventilation, and Air Conditioning) Systems

Process Piping in Manufacturing

Commercial Building Pipework

Residential Plumbing Systems

Connect with us for tailored insulation solutions that redefine comfort.

Click ‘Get in Touch’ and let’s elevate your space together.