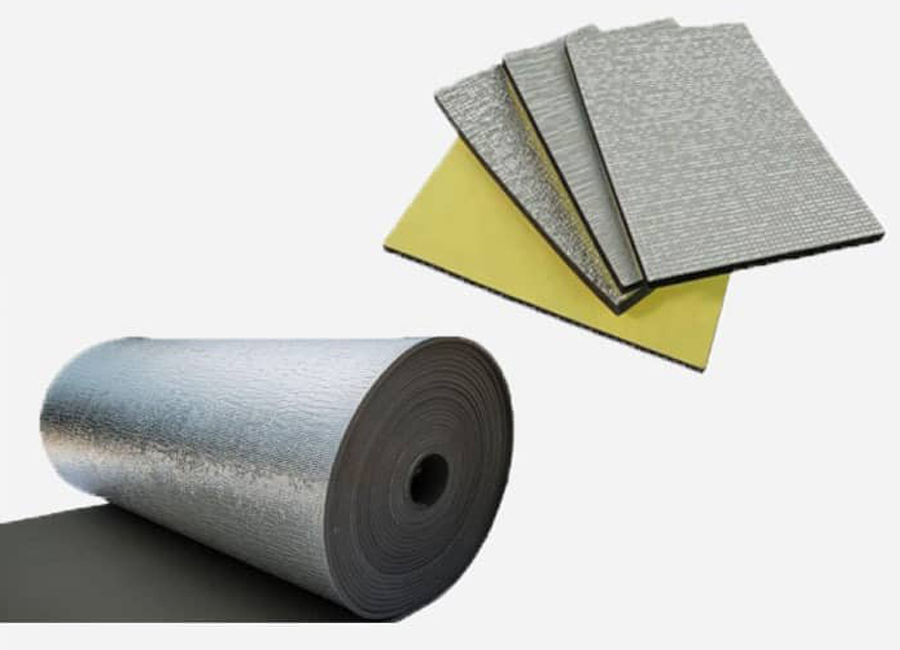

XLP Sheet Insulation

XLP sheet insulation refers to a type of insulation material made from cross-linked polyethylene (XLP) foam. This foam insulation is commonly used for thermal insulation and may have other properties such as moisture resistance and sound absorption.

Key Features

XLP sheet insulation provides effective thermal insulation by reducing heat transfer through conduction. It helps maintain desired temperatures in buildings and equipment, improving energy efficiency and reducing heating or cooling costs.

Some XLP sheet insulation products are designed to be resistant to moisture, preventing water absorption and maintaining their insulation properties even in humid conditions. This moisture resistance helps prevent mold, mildew, and corrosion.

XLP foam insulation may offer sound-absorbing properties, reducing noise transmission and improving acoustics in buildings, vehicles, or machinery.

XLP sheet insulation is typically durable yet lightweight, making it easy to handle, transport, and install. Its durability ensures long-term performance and resistance to wear and tear.

XLP sheet insulation is versatile and can be used in various applications, including walls, roofs, floors, HVAC ducts, pipes, vehicles, and industrial equipment.

Depending on the specific product and formulation, XLP sheet insulation may have fire-resistant properties, meeting fire safety standards and regulations.

Some XLP foam insulation products are resistant to chemicals, oils, and solvents, ensuring compatibility with different environments and applications.

Many XLP foam insulation products are manufactured using environmentally friendly processes and materials, contributing to sustainability efforts.

Applications

Residential

Buildings

Commercial

Structures

Industrial

Facilities

Educational

Institutions

Healthcare

Facilities

Bubble Insulation

SSV Insulation specializes in providing high-quality bubble insulation solutions tailored to meet the unique needs of residential, commercial, and industrial buildings.

Key Features

SSV Insulation sources premium-grade bubble insulation materials known for their durability, thermal performance, and moisture resistance. The insulation consists of multiple layers of low-density polyethylene (LDPE) bubble film sandwiched between reflective foil surfaces made of aluminum or metallized polyester.

Our bubble insulation is designed to provide exceptional thermal insulation by effectively reducing heat transfer through radiation. The reflective foil surfaces reflect radiant heat away from the surface, while the air bubbles act as a thermal barrier, slowing down heat flow. This results in improved energy efficiency, reduced heating and cooling costs, and enhanced indoor comfort.

SSV Insulation’s bubble insulation is versatile and flexible, allowing for easy handling, cutting, and installation. It can be used in a wide range of applications, including walls, roofs, attics, crawl spaces, HVAC ducts, and metal buildings. Whether for new construction or retrofit projects, our bubble insulation offers a cost-effective and efficient solution.

Our bubble insulation is resistant to moisture, making it suitable for use in areas prone to humidity or condensation. Proper installation and sealing of seams ensure excellent moisture resistance, helping to protect the building envelope and prevent mold or mildew growth.

The high reflectivity of SSV Insulation’s bubble insulation surfaces ensures effective radiant heat reflection, reducing the heat absorbed by the building envelope. This not only improves indoor comfort but also reduces the load on HVAC systems, leading to energy savings and lower utility bills.

Our bubble insulation products meet or exceed industry standards, building codes, and fire safety regulations. We prioritize safety and ensure that our insulation solutions provide reliable performance while adhering to all necessary safety requirements.

In addition to supplying premium bubble insulation materials, SSV Insulation offers expert installation services. Our skilled technicians ensure precise and efficient installation, maximizing the benefits of bubble insulation for our clients.

SSV Insulation’s bubble insulation solutions are cost-effective, offering an excellent return on investment through energy savings, improved thermal comfort, and long-lasting performance.

Applications

HVAC (Heating, Ventilation, and Air Conditioning) Duct Insulation

Chilled Water Pipe Insulation

Refrigeration Systems Insulation

Air Handling Units Insulation

Industrial Equipment and Piping Insulation

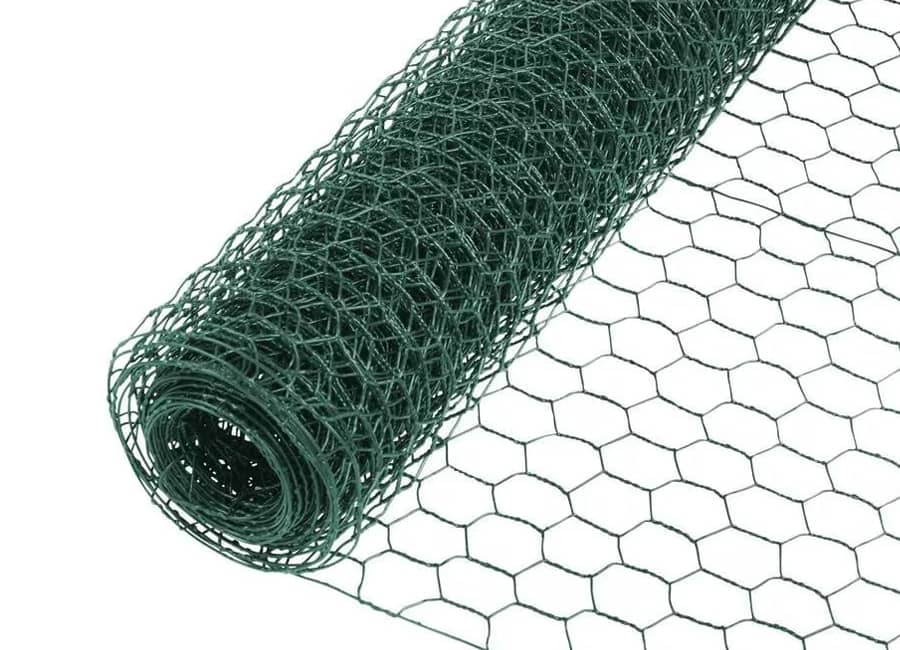

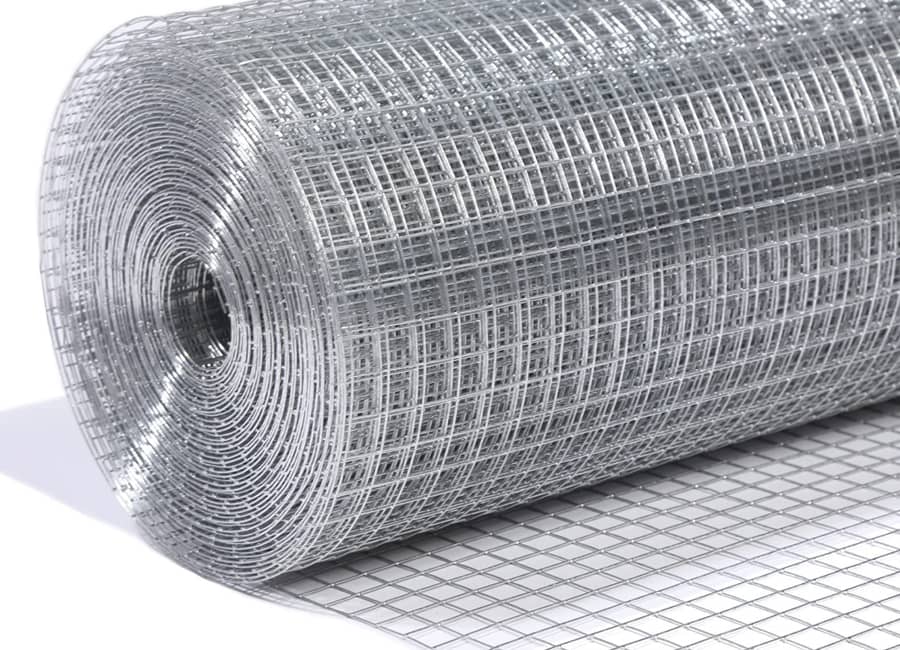

GI Wire Netting

Galvanized iron (GI) wire netting is a versatile and widely used material in construction, agriculture, fencing, and other applications where a durable and corrosion-resistant mesh is required.

Key Features

GI wire netting is typically made from high-quality steel wire that has been coated with a layer of zinc through a process called galvanization. This zinc coating provides excellent corrosion resistance, making the wire netting suitable for outdoor use and exposure to moisture and harsh weather conditions.

GI wire netting is available in various mesh sizes and wire gauges to suit different applications. The mesh size refers to the spacing between adjacent wires in the netting, while the wire gauge indicates the thickness or diameter of the wire. Common mesh sizes range from small, fine meshes used for insect screening to larger meshes used for fencing and construction reinforcement.

Galvanized iron wire netting is known for its strength and durability. The galvanization process enhances the wire’s resistance to corrosion, rust, and mechanical damage, ensuring a long service life even in harsh environments. This makes it ideal for applications requiring sturdy and reliable mesh, such as fencing, animal enclosures, and construction reinforcement.

GI wire netting is a versatile material with a wide range of applications. It can be used for fencing to enclose gardens, agricultural fields, livestock, and poultry farms. It is also used for screening windows and doors to keep out insects while allowing airflow. Additionally, GI wire netting is employed in construction as reinforcement for plastering, concrete, and masonry work to improve structural strength and prevent cracking.

GI wire netting is easy to install and can be cut to size using simple tools like wire cutters or shears. It can be attached to existing structures or supports using nails, staples, or wire ties. For fencing applications, it can be stretched between posts or attached to wooden or metal frames to create a secure enclosure.

Compared to other materials like stainless steel or aluminum, galvanized iron wire netting is often more cost-effective while still providing excellent corrosion resistance and durability. This makes it a popular choice for budget-conscious projects without compromising on quality or performance.

While GI wire netting is highly resistant to corrosion, periodic maintenance may be required to remove dirt, debris, or vegetation that can accumulate on the surface over time. Regular inspections and cleaning can help prolong the lifespan of the netting and ensure optimal performance.

Applications

Industrial

Processes

HVAC (Heating, Ventilation, and Air Conditioning) Systems

Commercial

Building Insulation

Residential

Construction

Equipment

Insulation

GI Wild Mesh

GI wild mesh, also known as galvanized iron wild mesh, is a type of wire mesh commonly used in agricultural and horticultural applications to protect crops and plants from wild animals and pests.

Key Features

GI wild mesh is typically made from galvanized iron wire, which is steel wire coated with a layer of zinc through the process of galvanization. This zinc coating provides excellent corrosion resistance, making the mesh suitable for outdoor use and exposure to harsh weather conditions.

GI wild mesh comes in various mesh sizes and wire gauges to suit different applications and levels of protection. The mesh size refers to the spacing between adjacent wires in the mesh, while the wire gauge indicates the thickness or diameter of the wire. Common mesh sizes range from small, fine meshes to larger meshes, depending on the type of crops and the size of the pests being targeted.

GI wild mesh serves as a physical barrier to prevent wild animals, birds, and pests from accessing crops and plants. It can be installed as fencing around agricultural fields, orchards, vineyards, and garden plots to deter animals from damaging or eating the produce. The sturdy construction of the mesh provides reliable protection against larger animals such as deer, rabbits, and birds.

In addition to protecting crops from wildlife, GI wild mesh has other uses in agriculture and horticulture. It can be used to create trellises for supporting climbing plants such as tomatoes, beans, and cucumbers. The mesh can also be employed as a barrier to prevent soil erosion or to support netting for shade or frost protection.

GI wild mesh is relatively easy to install and can be cut to size using simple tools such as wire cutters or shears. It can be attached to existing structures or posts using nails, staples, or wire ties. For larger installations, it can be stretched between posts or attached to wooden or metal frames to create a secure perimeter.

The galvanized iron construction of the mesh provides excellent durability and resistance to rust and corrosion, ensuring a long service life even in harsh outdoor environments. This makes GI wild mesh a cost-effective solution for long-term crop protection.

While GI wild mesh requires minimal maintenance, periodic inspections may be necessary to ensure that the mesh remains intact and properly secured. Any damage or areas of weakness should be repaired promptly to maintain the effectiveness of the mesh as a barrier against wildlife.

Applications

Industrial Piping Systems

HVAC (Heating, Ventilation, and Air Conditioning) Systems

Process Piping in Manufacturing

Commercial Building Pipework

Residential Plumbing Systems

Connect with us for tailored insulation solutions that redefine comfort.

Click ‘Get in Touch’ and let’s elevate your space together.